Audio Electronics Sector Feels the Heat: India’s audio electronics industry is facing a serious setback. Over 21,000 jobs are at risk after China tightened export rules on key rare earth elements. The restriction, in place since April, affects materials like dysprosium and terbium—critical for manufacturing high-performance magnets.

Magnets Powering Modern Devices

These metals are used to produce NdFeB (Neodymium-Iron-Boron) magnets, vital components in speakers, earbuds, and other consumer electronics. The shortage has disrupted local production, forcing companies to import fully assembled modules from China instead of making parts in India.

Factories in Noida and South India at Risk

According to industry body ELCINA, the shift from component production to full imports threatens thousands of jobs. Between 5,000–6,000 direct jobs and 15,000 indirect ones in Noida and South India could be lost if the trend continues.

Heavy Import Dependence Deepens the Crisis

India currently imports nearly 90% of its NdFeB magnets from China. With the new curbs, prices have soared. Alternative sources like the U.S., EU, and Japan are too expensive and lack the capacity to meet India’s fast-growing needs.

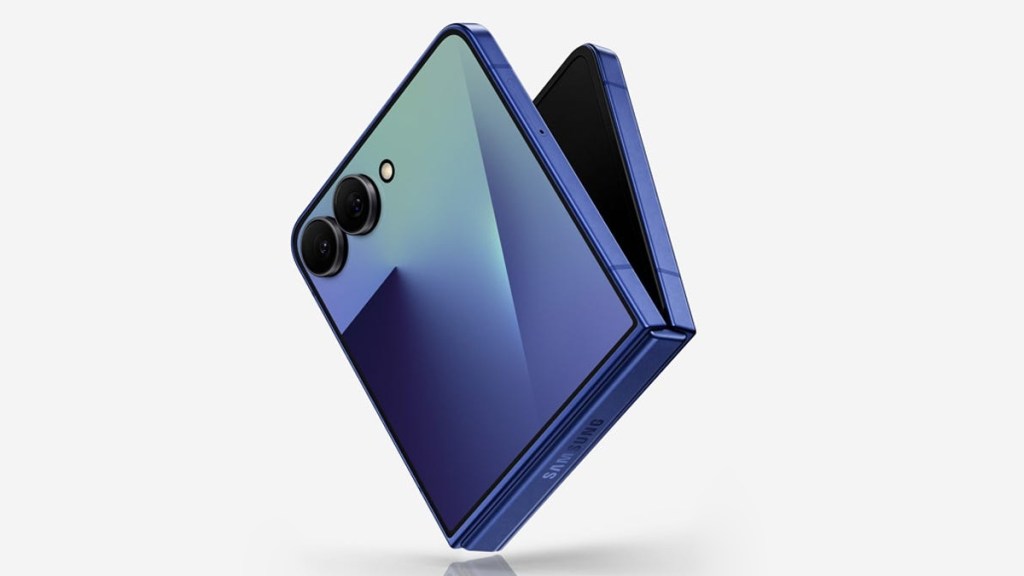

Impact on TVs Likely Smaller—for Now

TV maker Videotex, which supplies to brands like Toshiba and Reliance, said speaker magnet shortages pose a concern. However, they expect minimal impact on their segment due to current stock levels. The company is also exploring ferrite magnets as a temporary fix.

Call for Policy Action and Local Manufacturing Push

ELCINA has urged the Indian government to begin high-level talks with China to ease the restrictions. It also recommends boosting domestic magnet manufacturing through R&D investment and incentives under existing electronics policies.

A new Production-Linked Incentive (PLI) scheme focused on critical minerals has also been proposed.

Final Thoughts: A Wake-Up Call for India’s Tech Industry

This disruption highlights India’s overdependence on imported components. Without a long-term strategy for local sourcing and production, similar crises could repeat. The time to diversify and invest in domestic tech manufacturing is now.